Mould design is the

lifeblood of Bipiemme srl.

The design team avails itself of the most up-to-date, high-performance two- and three-dimensional CAD drawing tools, and can tackle any challenge: from traditional to more complex moulds, from two-material to sandwich moulds, high-precision and aesthetically pleasing.

Product design is monitored&

at every step.

Crucial for precisely defining the geometries of each individual component. Two-dimensional design provides key information on dimensional aspects, tolerances, surface finishes and other critical details required for mould production.

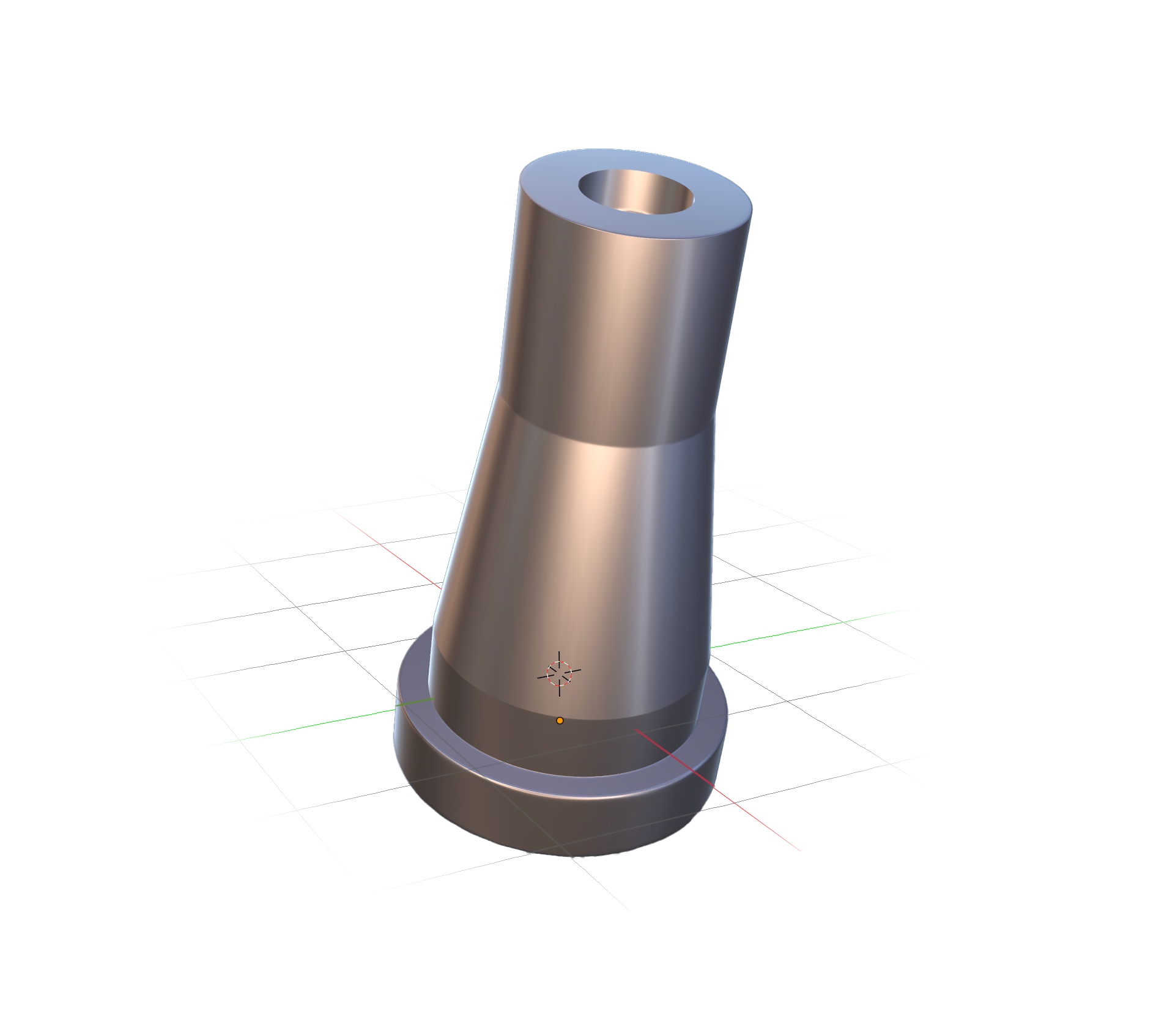

A critical process for creating detailed digital models of mould components using CAD software. These three-dimensional models allow designers to visualise the geometry of moulds in an accurate and detailed manner before they are physically produced.

Through the use of 3D printing technologies, we create models and prototypes of moulds or their individual components. This process allows us to test and validate mould design quickly and efficiently before starting large-scale production.